The unboxing, boxing, and sealing machine is an automated equipment that integrates unboxing, boxing, and sealing, widely used in e-commerce logistics, express logistics, warehousing logistics, and other scenarios. It can automatically complete the operations of unboxing, boxing, and sealing, significantly improving logistics and distribution efficiency, reducing labor costs, and improving work quality.

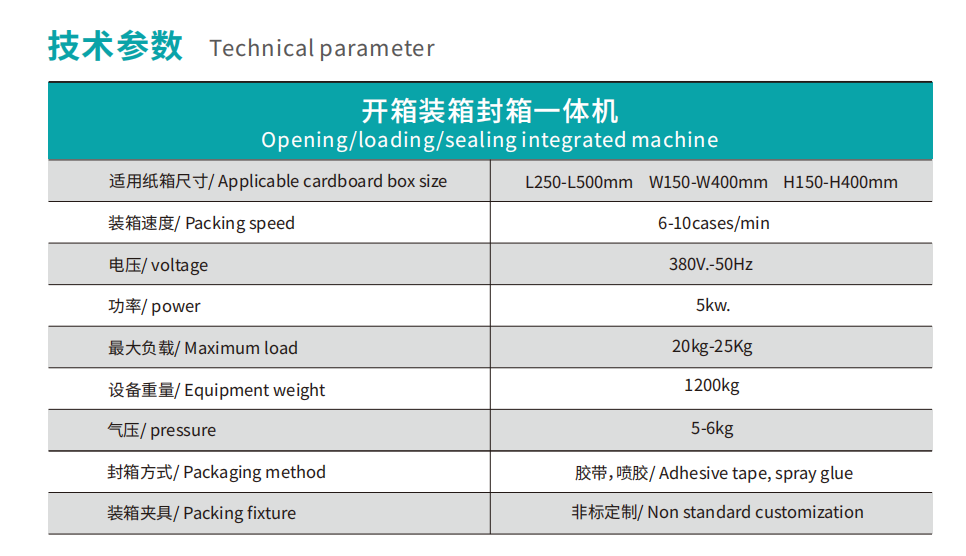

Technical parameters and design principles:

The design principle of the integrated unboxing, boxing, and sealing machine is to efficiently integrate the functions of unboxing and sealing. Through precise mechanical structure and advanced automation control technology, it realizes the automation processing of a series of processes from packaging material supply, box forming, item loading to box sealing. The equipment utilizes sensors to accurately identify packaging materials, and controls the robotic arm or conveyor belt through a programmable logic controller (PLC) to feed the packaging materials into the forming area, quickly folding and fixing them into a standard box shape. The items are accurately placed in the formed box through an automatic conveying system, and finally the box cover is tightly sealed with the box body through a heating device or a pressing mechanism, and necessary labels or barcodes are affixed.

Main functions and advantages:

1. Improving logistics and distribution efficiency: Compared to traditional manual operations, all-in-one machines can greatly save time and labor costs, significantly improving logistics and distribution efficiency.

2. Reduce labor costs: Automatically complete unboxing, boxing, and sealing operations, reducing reliance on manual labor and lowering labor costs.

3. Improving work quality: Avoiding omissions and errors in manual operations and enhancing work quality.

4. Space saving: does not require a large amount of manual operation space, can save space.

Equipment characteristics:

1. The opening and sealing integrated machine equipment occupies 50% less space compared to the split combination equipment.

2. The overall safety of the equipment is extremely high, with all peripherals protected by 10MM thick organic glass, and an alarm for door opening and shutdown, preventing personnel from making any dangerous movements.

3. Stable and fast operation, according to the actual appearance and production capacity of the product, the packing action can be completed 6-10 times per minute.

4. The unboxing mechanism adopts an "L" shape for unboxing, requiring the bottom of the cardboard box to ensure the success rate of unboxing.

5. The product adopts dual servo material handling, which is faster, more accurate, and stable.

6. The whole machine adopts servo motor control, which runs more accurately, stably, and is easy to operate.

7. The equipment system and institutional equipment are independently developed and manufactured, which is more convenient for later maintenance and has lower maintenance costs.

The integrated machine for opening, packing, and sealing boxes has a wide range of applications in various industries, including food, medicine, electronics, and logistics.

Application scenarios:

1. Food industry: In the food industry, the box opening and sealing machine is used for packaging biscuits, candies, chocolates and other foods. It can automate the opening, packing, and sealing of boxes, improve packaging efficiency, reduce labor costs, and adjust packaging dimensions according to packaging requirements, reducing the use of packaging materials.

2. Pharmaceutical industry: In the pharmaceutical industry, this equipment is used for packaging drugs, medical devices, etc. It can achieve automated packaging, avoid the risk of cross infection in manual operations, reduce the use of packaging materials, and lower packaging costs.

3. Electronics industry: In the electronics industry, such as the packaging of electronic products such as computers and mobile phones, an integrated machine for opening, packing, and sealing boxes can improve packaging efficiency, reduce labor costs, and adjust packaging dimensions according to packaging requirements, thereby reducing packaging costs.

4. Logistics industry: In the fields of express delivery, logistics, etc., this equipment can greatly improve packaging efficiency, reduce labor costs, and adjust packaging size according to packaging requirements to reduce packaging costs.