The high-speed vertical servo sealing and shrinking machine is a packaging equipment that combines high-speed servo motors and vertical sealing and shrinking technology, mainly used for efficient and precise sealing and shrinking packaging of products. The device adopts a fully automatic design, combined with high-speed servo motors, which can achieve high-precision position control and fast response, ensuring accurate and error free sealing and cutting every time.

Working Principle:

The workflow of the high-speed vertical servo sealing and cutting shrinking machine is as follows:

1. Material transportation: Materials enter the working area of the sealing and cutting machine through a conveyor.

2. Sealing and cutting processing: The equipment automatically completes the measurement, cutting, and sealing work according to the set program.

3. Shrink packaging: After the sealing and cutting are completed, the product enters the shrink device and is tightly adhered to the surface of the product through thermal shrinkage, completing the entire packaging process.

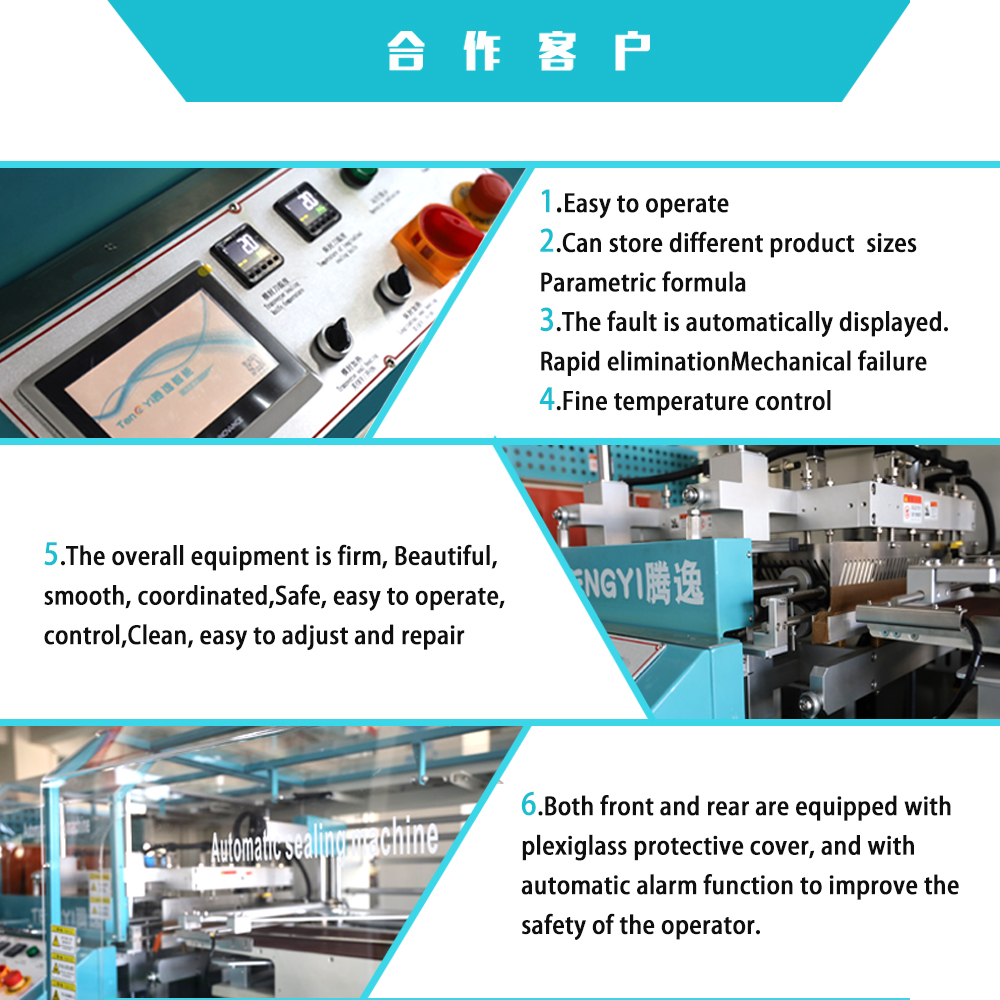

This type of machine typically has the following characteristics:

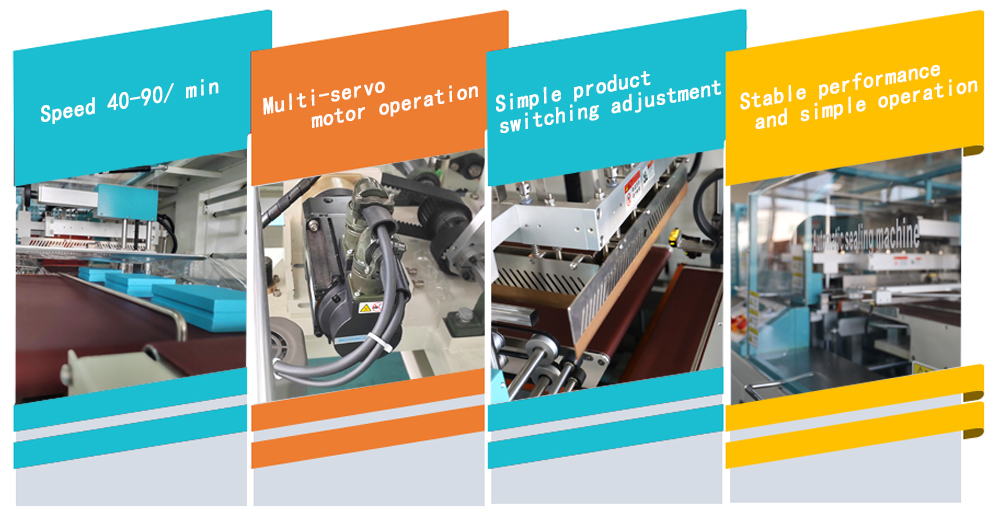

1. Precise control: Adopting advanced servo control system, it can accurately adjust the sealing temperature and conveying speed, ensuring the stability and efficiency of the packaging process.

2. Efficient and energy-saving: Using quartz far-infrared tubes for heating has a significant energy-saving effect, usually saving more than 15% of electricity.

3. Wide applicability: Suitable for various industries such as food, beverage, cosmetics, electronic products, toys, etc., widely used in the fields of pharmaceuticals, food, stationery, cosmetics, electronic products, toys, etc.

4. High degree of automation: The fully automatic heat shrink packaging machine adopts automatic sealing and cutting functions. Simply place the product in position and start the switch to automatically complete the sealing process, suitable for large-scale production.

5. Wide adjustment range: The contraction temperature and motor transmission speed are stable and adjustable, with a wide adjustment range, suitable for products of different sizes and shapes.

Application Scenarios:

High speed vertical servo sealing and cutting shrinking machines are widely used in various industries such as food, medicine, and daily necessities. In the food industry, it is used to package snack products such as cookies, candies, chocolates, etc; In the pharmaceutical industry, it is used for packaging drugs, health products, etc; In the daily necessities industry, it is used to package various liquid and solid products.

Market Prospects and Development Trends:

With the rapid development of e-commerce and the increasing emphasis on packaging efficiency and quality in various industries, the demand for high-speed vertical servo sealing and cutting shrinking machines is constantly increasing. In the future, this device will develop towards higher levels of intelligence, multifunctionality, and environmental friendliness. The development of intelligence will enable it to have functions such as remote monitoring and fault diagnosis; Multi functionality will meet the diverse needs of different industries; Environmental design will reduce energy consumption and exhaust emissions.