Cuff type film packaging machine is a common automated packaging equipment, mainly used for packaging food, medicine, cosmetics and other items. This device can automatically complete a series of functions such as sealing, packaging, and cutting, greatly improving packaging efficiency and preservation effect, and therefore has been widely used.

Working Principle:

The working principle of cuff type film wrapping machine is based on the characteristics of heat shrinkable film. Heat shrink film is a special type of plastic film with a certain degree of shrinkage. When the film is heated to a certain temperature, it will shrink, causing the film to adhere tightly to the surface of the product. During the packaging process, the product is placed on a conveyor belt and covered with a heat shrinkable film through an automatic film feeding device. The film is then heated by a heating device to shrink and adhere tightly to the surface of the product. Finally, the film is shaped by a cooling device to complete the entire packaging process.

Main Features:

1. High speed: The cuff type film wrapping machine can achieve high-speed sealing, packaging, cutting and other functions, greatly improving packaging efficiency.

2. Multi functional: This device can achieve various functions such as flat sealing, cuff sealing, vertical sealing, three side sealing, and four side sealing, and is suitable for different types of bags.

3. Good stability: By adopting advanced control systems and electronic components, the stability and reliability of the equipment have been improved, and the failure rate has been reduced.

4. Easy to operate: The control panel is simple and easy to understand, making it easy for both experienced and new employees to get started.

5. Environmentally friendly and efficient: Adopting advanced heating technology, it can quickly and uniformly heat the film, reduce energy waste, and conform to the concept of sustainable development.

Technical Characteristics:

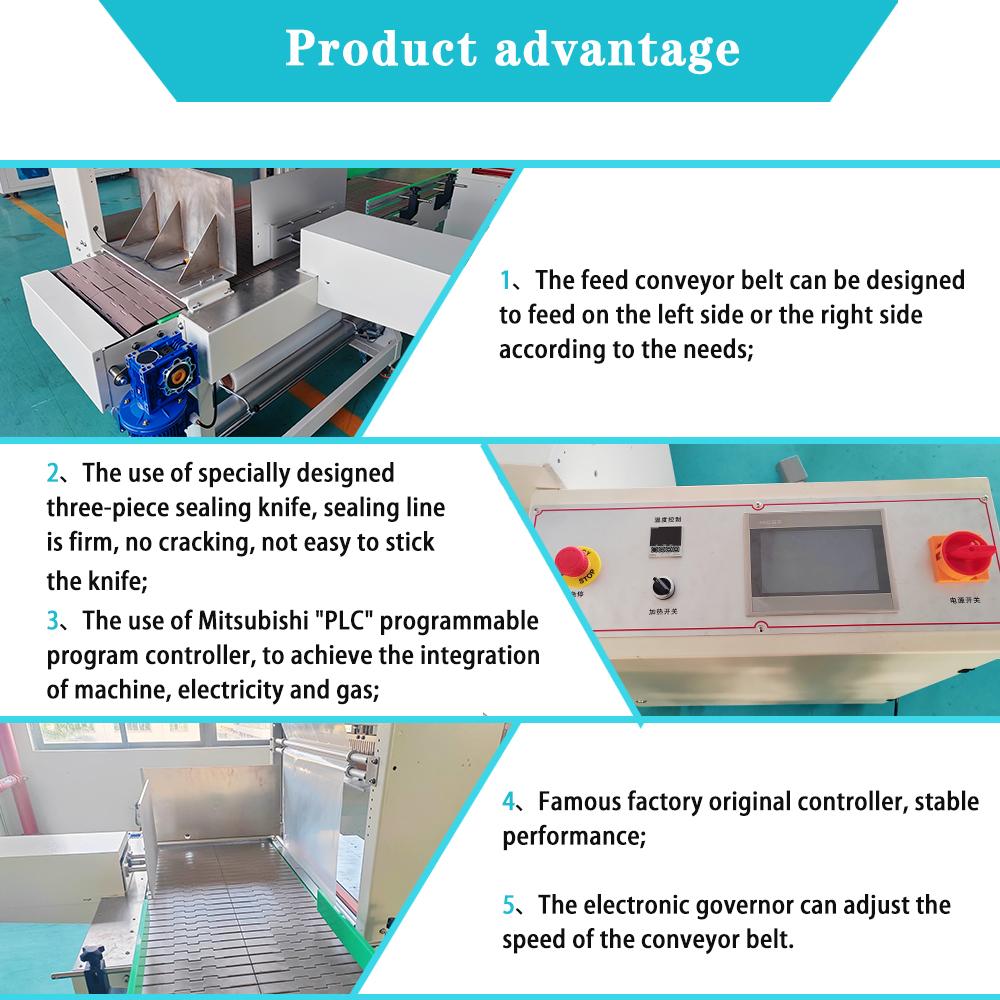

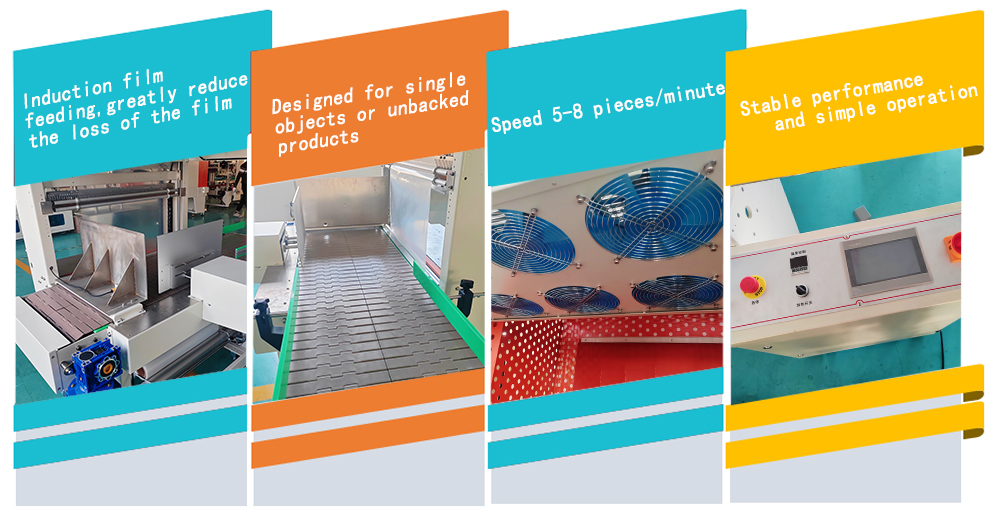

1. Designed for single objects or unbacked products;

2. This machine is connected with the production line to automatically feed, wrap film, seal and cut, shrink, cool and finalize;

3. Induction film feed, greatly reduce the loss of film;

4. OMRON"PLC" programmable controller is adopted to realize the integration of machine, electricity and gas;

5. Specially designed three-piece sealing knife, the sealing line is firm, no cracking, not easy to stick the knife;

6. The feed conveyor belt can be designed to feed on the left side or the right side according to the needs.

Application Area:

1. Food industry: used for packaging bagged beverages, puffed foods, nuts, dried fruits, etc., which can effectively maintain the freshness and extend the shelf life of food.

2. Pharmaceutical industry: used for packaging drugs, such as granules, capsules, small package tablets, etc., which can effectively prevent drugs from being contaminated or damp during transportation and storage.

3. Cosmetics industry: It is used for packaging facial mask, facial cleanser, lotion and other cosmetics, which can improve the appearance grade and added value of products.

4. In the daily necessities industry, packaging for products such as shampoo and shower gel can improve their appearance and protective performance.

5. Electronic product industry: Used for packaging small electronic products such as USB drives, headphones, etc., which can effectively protect products from external environmental influences.

6. Toy industry: providing beautiful and practical packaging solutions for toy products.